ORC Generator

ORC Generator

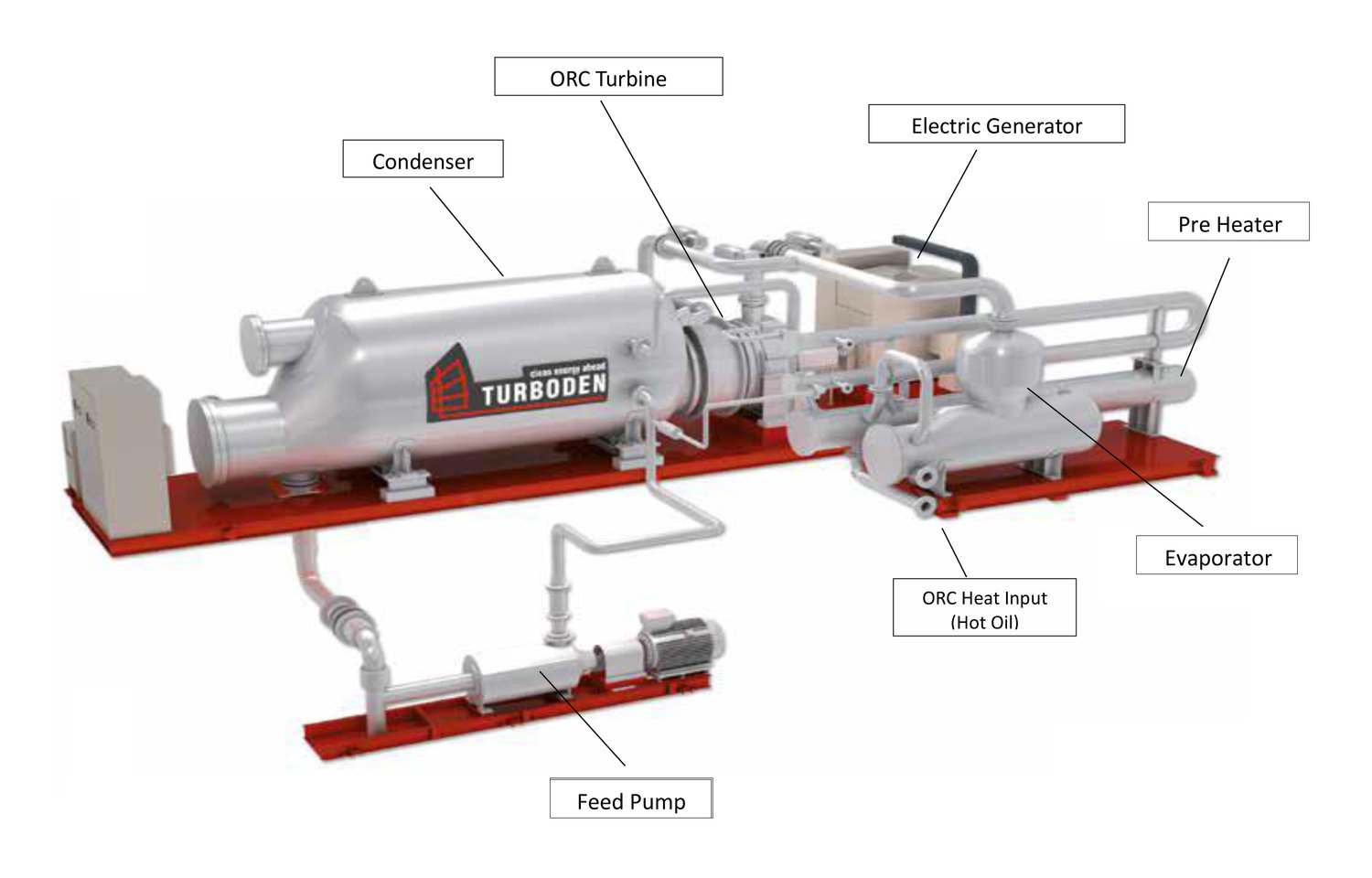

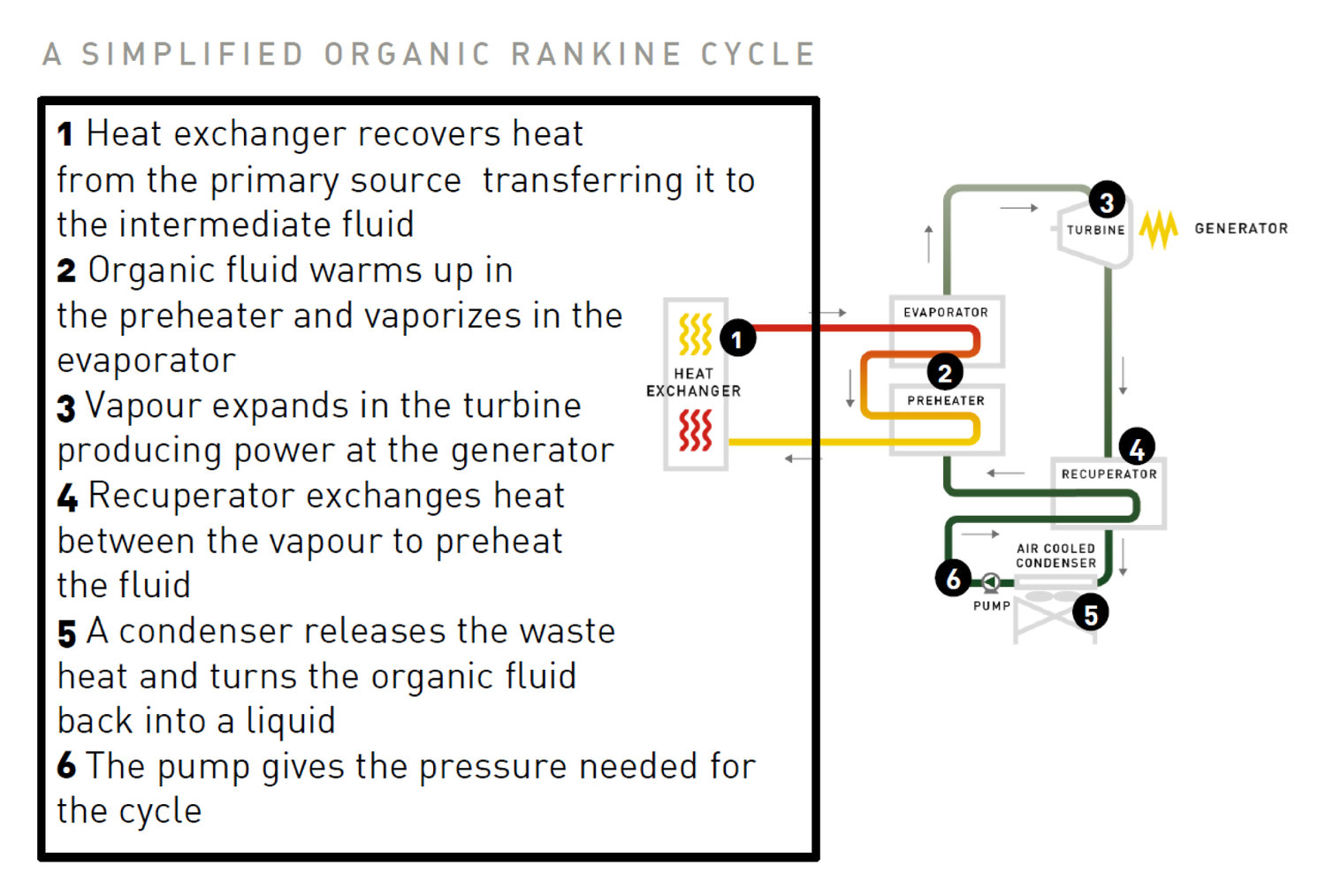

The pressurized vapor, moves into the ORC turbine unit, passing across the blades which are connected by a shaft to a generator. This is the fundamental action that creates electricity. What makes ORC so useful to remote community application is its lower operating pressures, and consequently its relatively straight forward and predictable maintenance requirements. Unlike high pressure steam systems, corrosion is not an issue, requiring much less constant observation and thus creating significantly lower risk of material shutdown and maintenance. In addition, being low pressure, ORC systems experience a far lighter load on equipment and operators, making monitoring and response a much more predictable task.

There are no fluid losses or emissions from the thermal oil or from the working fluid because they are both retained in the closed loops of steel tubes. However as temperature of the working fluid is increased until it turns into a vapor (boiled) and then decreased ( condensed) until it turns into a liquid again, all ORC systems require the working fluid to be cooled . This is typically in remote locations using air cooling units as the simplest solution. These units use large fans to blow cool air across the vapor loop as it enters the condenser phase. Relatively simple, and inside the plant, these ORC closed loop systems operate seamlessly worldwide.